Labor Regelungs- und Automatisierungssysteme

Automation Systems

Profile and objectives

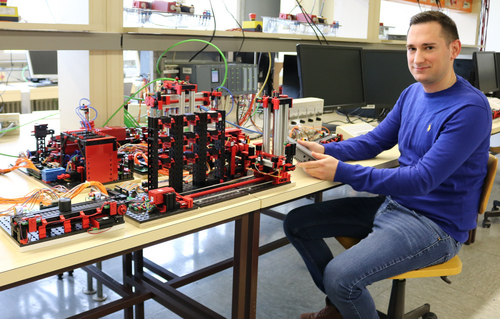

The laboratory provides students with the opportunity to apply and deepen the contents of automation technology lectures in a practical manner. We offer modern equipment for industrial automation systems that enables students to directly apply their theoretical knowledge in practice.

In our well-equipped laboratory, students can explore various aspects of control engineering and automation technology, ranging from programming automation systems to controlling production processes and designing control systems. These hands-on experiences help students develop a better understanding of industrial technology and acquire essential skills for future careers in this field.

Equipment

Automation Systems:

- 8 PLC (Programmable Logic Controller) lab workstations with Siemens TIA Portal software (latest version), analog and digital input/output modules, as well as touch and control panels

- 4 SIMATIC S7 1500 F with integrated safety features and various peripherals

- 4 SIMATIC S7 1500 with various peripherals

- 4 SIMATIC S7 300 with various peripherals - 8 lab workstations with CODESYS Development System

- 8 Remote I/O (Decentralized Peripherals ET200 MP by Siemens)

- 15 CODESYS Soft-PLCs (CODESYS Control Win, www.codesys.com) - 8 workstations with MATLAB software and corresponding toolboxes

- Various plant models by Fischertechnik (10 conveyor belts, 8 sorting stations, 8 multi-processing stations, 4 vacuum grippers, 2 high-bay storage systems)

- 2 Process Automation Controllers: freely programmable (SIMATIC OPEN Controller CPU 1515SP)

- 9 programmable logic modules/compact PLCs (Siemens LOGO!)

- 3 RFID systems (SIMATIC RF200 Readers with transponders connected via IO-Link)

- 4 Internet of Things - Open-Source platforms (SIMATIC IOT2040)

- 2 Process Control Systems PCS 7 (Controllers with ET200M)

- 4 electrical drive systems with conveyor belt applications (1 x SINAMICS S120 and 3 x SINAMICS Servo Converters S210)

- 4 safety systems: safety door with safety position switch (Edison MKEY), emergency stop, safety PLC

- 1 portal robot by Festo

- Various 3D-printable articulated robots (in-house development)

Control Engineering Experimental Setups:

- 2 workstations for basic exercises with the Bode diagram

- 3 sway control systems

- 4 liquid flow control systems

- 6 Process Control Boards with various controllers and plants

Internships and Tutorials

Various courses are offered in the laboratory. It is recommended to attend the laboratory sessions concurrently with the corresponding lectures:

- Automation Systems Laboratory

- Control and Automation Systems Laboratory 1

- Control and Automation Systems Laboratory 2

The laboratory exercises cover various topics, including:

- Determination of system parameters using frequency response analysis (Bode diagram)

- Design and simulation of basic controller types P, PI, and PID controllers

- Controller design using Bode diagram, Kessler method, and Chien-Hrones-Reswick method

- Design and simulation of discrete PID controllers

- Cascade control of an industrial level control system

- Motion control of a robot with RTT kinematics

- Programming according to DIN EN 61131-3 in Function Block Diagram (FBD), Sequential Function Chart (SFC), Structured Text (ST), as well as to a lesser extent Ladder Diagram (LD) and Instruction List (IL).

- Design of interlocking functions, interlocking controls, and sequence controls

- Configuration of PLCs of the SIMATIC S7 series and CODESYS Soft-PLC Win Control Motion-Control

Internships can also be completed in the laboratory (as part of a university program).